This article will focus on explaining the various techniques of manufacturing tuning forks to help bring awareness of features that will be indicative of a tuning forks quality or the lack thereof.

We will also bring awareness to some of the language used to give the impression of quality despite being little more than advertising hype.

All manufacturing processes leave unique features that are essentially “fingerprints” revealing how a tuning fork was manufactured and tuned. By understanding the nature of these fingerprints we can identify the process and thereby evaluate the quality and care that was used during the process of creation.

Here we will discuss how to identify these features so that you can be aware of what to look for when assessing the quality of tuning forks.

What materials are tuning forks made from and how does this effect tone and sustain of the vibration.

Explore various production techniques and surface finishes produced by processes such as CNC milling, manual milling, or drilled and sawn.

Learn to recognize quality in the finish on the ends of the fork tines.

Learn why consistent thickness of tines is important.

By inspecting the base of the tines we can determine the production process and its effect on quality.

See various types of weights and features that show quality.

Forks can have a large variation in the length of the handle,

Techniques for tuning and notes on precision.

Tuning forks can be produced from a wide range of raw materials including aluminum, steel, stainless steel, copper, and brass among others.

Each material provides its own unique spectrum of harmonics and duration of vibration.

In this article we will explore the quality characteristics related to tuning forks manufactured from aluminum.

Sacred Innovations offers a selection of tuning forks crafted exclusively from aluminum due to its exceptional range of harmonics. It’s worth noting that some suppliers may assert that their tuning forks are fashioned from “Aircraft grade aluminum” to create an impression of superior quality. In reality, these are common grades of aluminum, which finds application in a broad spectrum of industries, encompassing furniture, appliances, marine, automotive, and aviation.

It’s important to be aware that certain manufacturers opt for cast aluminum instead of high-quality aluminum alloys. It is strongly recommended to steer clear of tuning forks fabricated from cast aluminum, as they tend to exhibit inferior harmonic spectra and sustain times.

Sacred Innovations utilizes only premium grade aluminum for our tuning forks. As a result our forks exhibit exceptional tonal qualities and extended sustain time.

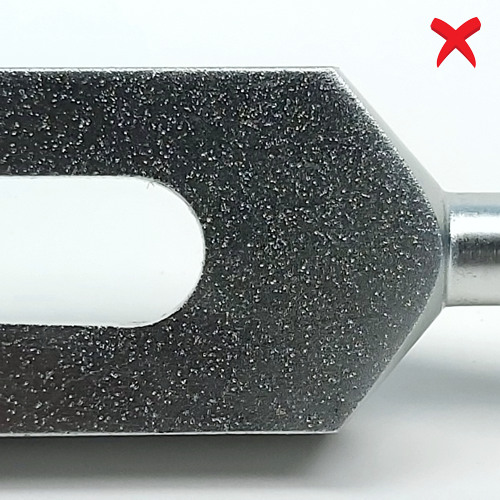

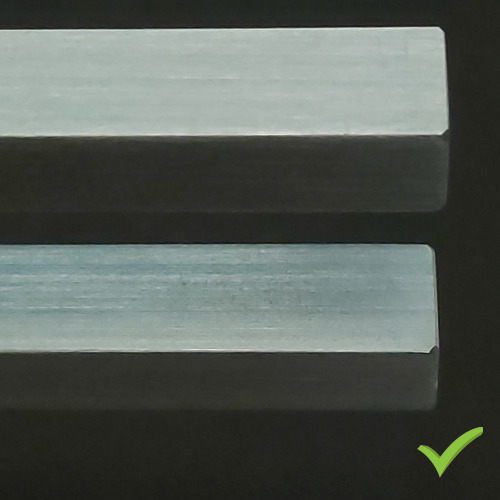

These images are illustrating the surface texture of extruded aluminum with a brushed finish (on the left) in comparison to cast aluminum (on the right). It’s essential to observe the dimpled texture of the cast aluminum’s surface. These “dimples” are, in reality, voids within the aluminum, originating from the casting process. These microscopic air bubbles form within the material, resulting in porosity that permeates the metal, ultimately affecting its density and consequently its resonant properties.

Conclusions : By carefully looking at the surface finish of the metal you can easily determine if it is cast aluminum. Sacred Innovations uses only premium quality aluminum alloys for our tuning forks.

The surface texture becomes very apparent when viewed under a microscope. as seen here.

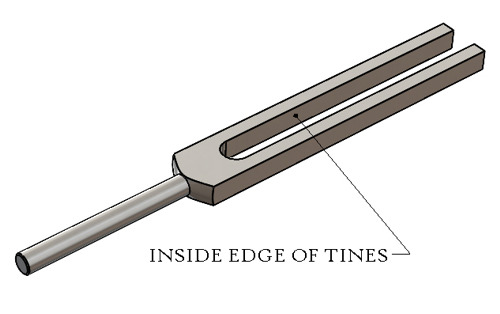

Tuning forks are typically produced from flat bar stock then the material is cut away to leave the two tines at each side.

By examining the surface finish on the inner edge of the tuning fork tines we can gain insights to the processes used to manufacture them which will offer clues to the quality of the fork.

There are three machining processes that could be used to remove the material between the tines. They are listed in order of quality starting with the best.

The process to produce the best quality tuning fork is CNC Milling which is short for Computer Numerical Control. These machines provide the ultimate in control of all factors effecting the machining process including spindle speed and cutting tool feed rate.

Can produce an equally good quality fork if cutting techniques are properly controlled. However it is more likely to have variances in cutting tool federate which could result in tool chatter or inconsistent surface finish.

This is a poor choice of process and usually results is a poor quality fork. This process begins by drilling a hole at the base of the tines. A bandsaw or circular saw is then used to make 2 cuts from the end of the fork to the hole. This cutting process leaves a very rough finish which is then sanded on a belt sander to smooth the inner face of the tines. This process leaves a very poor finish and is susceptible to have variances in the thickness of the tines which results in imbalanced sine wave generation and poor sound quality.

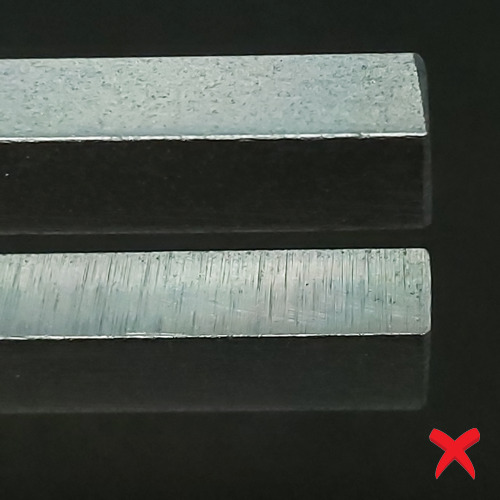

Here you will see two examples of techniques to cut away the material between the tines.

Note on the image to the right the vertical sanding lines found on poor quality forks. The lines can be seen to slope at an angle and not be perfectly vertical.

To the untrained eye the sanding lines could appear similar to the milling lines. To tell them apart look for consistent spacing the in the lines and they should always be vertical and parallel.

The critical features that make good quality tines are :

Conclusions : Look for tines that are made by CNC Milling and avoid all that show signs of being belt sanded on the inner faces.

Sacred Innovations uses CNC Milling to produce all our tuning forks.

By examining the ends of the tuning fork you can gain insights into the process used to tune the fork as well as a reflection of overall quality and care given during the manufacturing process.

The fundamental frequency of the fork is tuned by reducing the length of the tines. As the tines get shorter the fundamental frequency increases. Most commonly the length is reduced by a sanding process on a belt or disc sander. After tuning the ends of the fork should be finished to improve appearance and eliminate sharp edges.

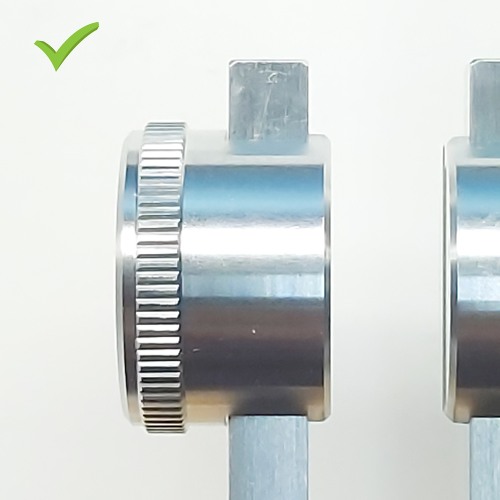

Example of a top quality fork produced by Sacred Innovations.

An example of a poor quality fork.

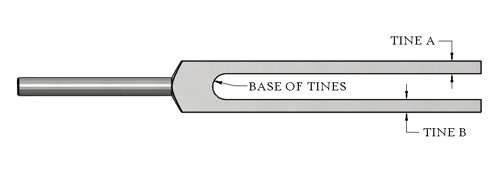

A critical feature of a good quality tuning fork is equal thickness of tines.

In a perfect world the thickness of Tine “A” would be exactly identical to the thickness of Tine “B”.

In the realm of manufacturing, even the smallest variations are inevitable. These minute discrepancies can have a significant impact, particularly in the context of tuning forks. When there is a difference in the thickness of the tines, it results in the production of an asymmetrical sine wave, thereby influencing the fork’s tone, harmonics, and the duration of its vibration.

To accurately gauge the thickness of the tines, specialized measuring instruments are required, such as a digital caliper or micrometer, with an accuracy level surpassing .0005″.

As a general guideline, the tolerance for thickness deviation in standard-sized forks should not exceed .004″, which is roughly equivalent to the diameter of a human hair. Ideally, it’s preferable to keep the deviation below .002″ for optimal performance.

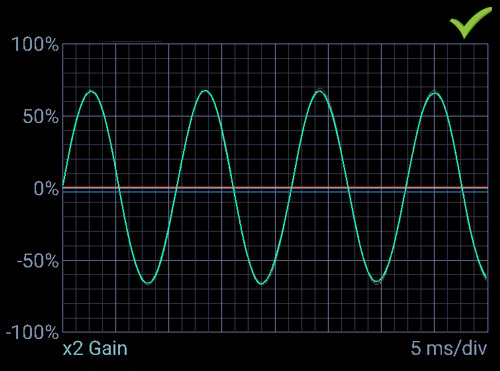

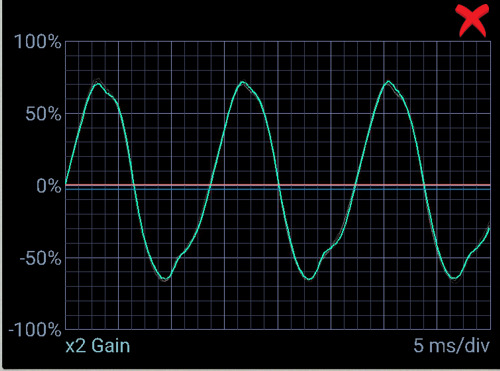

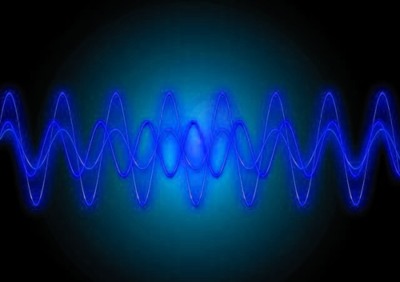

When the tine thicknesses are equal, the sine wave generated by the fork is well balanced. Note in this image the rising slope and falling slope angles are balanced. This results in good harmonics and good duration of vibration.

When the tine thicknesses are different the sine wave generated by the fork is imbalanced. Note in this image the rising slope and falling slope angles are imbalanced. This results in poor harmonics and short duration of vibration.

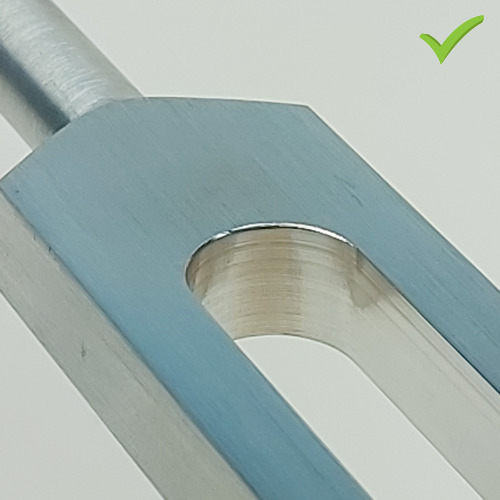

When inspecting the base of the tines it can show the characteristics of the process used to machine away the material between the tines.

Features to look for include :

The radius of the base should be smooth and consistent as shown here with this fork crafted by Sacred Innovations.

This image shows a fork that was produced by manual milling where the sequence of tool moves was not effectively executed. You can see a vertical line between two separate radii as well as tool chatter marks due to pausing of the cutting motion. These features will not influence the frequency of vibration or sustain but do indicate a lower level of quality.

This image shows a fork that was drilled, sawn, and sanded. This method of fabrication is used by those who don’t have the appropriate machinery to produce high quality forks. These would be low cost tuning forks with equally low quality and poor performance.

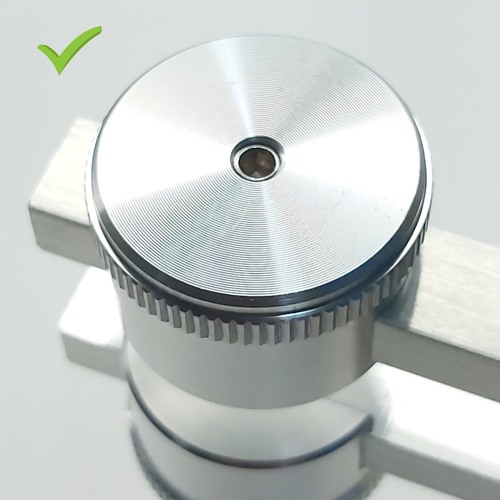

Weights can be affixed to a tuning fork, typically near the tines’ ends, in order to increase its mass. This modification leads to a decrease in the fundamental frequency of vibration, and such forks are commonly referred to as “weighted” tuning forks.

Moreover, the inclusion of these weights alters the harmonic composition produced by the fork. This adjustment tends to diminish the magnitude of the harmonics while simultaneously amplifying the amplitude of the fundamental frequency.

The weights used in this context are essentially circular aluminum components that are securely attached to the tuning fork’s tine using a small screw. The vibrational frequency can be finely adjusted by altering the placement of these weights.

These weights are available in various sizes, and all of them perform effectively. The critical factor to ensure is that the masses of the two weights on a single fork must be identical. Any disparity in mass between the two weights can create an imbalance in the fork’s vibration, resulting in subpar harmonics and a diminished vibrational period.

It’s worth noting that weights are inherently straightforward in their function, leaving very little room for complications. The visual appearance of the weight can indeed serve as an indicator of the fork’s quality, as illustrated below.

Surprisingly the design of the handle can effect the performance of the tuning fork. Longer is not always better, it depends upon your use of the fork which option may be best for you.

Be aware that some suppliers offer their forks with “extra long handles”. This may appear to be a bonus, however the additional mass of the extra length will reduce the sustain time of the forks vibration.

As with many things, finding the appropriate balance is the key.

Pros:

Pros:

In theory, the process of tuning a fork appears quite straightforward, but in practice, numerous influencing factors come into play.

The vibrational frequency of a tuning fork is primarily determined by the physical dimensions of its tines. Tuning the fork involves a relatively simple adjustment of altering the length and or mass of the tines. Shortening the tines or reducing the mass through a process of “hole tuning” will result in an increase in frequency.

The frequency of a fork can be adjusted in a number of ways:

One critical factor that demands consideration in the tuning process is the influence of temperature on the tuning fork.

Each step of the tuning procedure can generate heat, which, in turn, affects the fork’s frequency. Notably, processes like sanding can generate heat in the aluminum, causing it to expand and consequently elongating the tines, which reduces the frequency. As the fork cools, the aluminum contracts, resulting in a frequency increase.

To achieve precise tuning, it is imperative to cool the fork to a defined temperature, typically around 18-21 degrees Celsius, after each adjustment. This temperature stabilization is accomplished by immersing the fork in water of specific temperature before taking frequency measurements. This cooling and measurement process may need to be repeated multiple times to attain the desired level of precision for the tuning fork.

When each of these procedures is conducted patiently and meticulously, they can yield a well-tuned and high-quality tuning fork. After the tuning is completed, it is essential to finish the ends of the fork to eliminate any sharp edges.

If you measure a fork’s frequency and discover a discrepancy from your expectations, it is highly likely that the fork’s temperature differs from when it was initially tuned.

It’s worth noting that some suppliers of tuning forks may not account for thermal expansion in their tuning process. Consequently, the tuned frequency may be accurate but at a temperatures higher than the normal room temperature.

Sacred Innovation provides a certificate of tuning with each fork which shows the final frequency and temperature at which the fork was tuned.

Hole Tuning is a specialized process invented by Sacred Innovations to tune unweighted forks.

See the linked article to learn the details.

Sacred Innovations, your premier destination for precision instruments designed for sound therapy.

Copyright sacredinnovations.ca © All rights reserved