Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on the surface of metal parts, primarily aluminum and its alloys. The process creates a durable and corrosion-resistant coating on the metal, which can also provide enhanced wear resistance and improved aesthetics.

Dyes can be added to the anodizing bath to impart color to the metal.

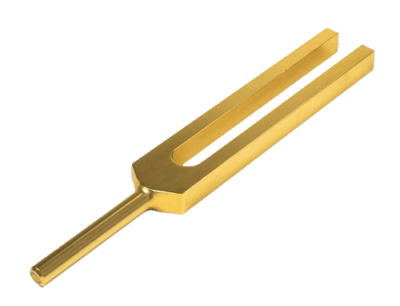

Anodizing is a versatile process that can produce a broad spectrum of colors on aluminum making it an attractive choice for both functional and aesthetic applications. The available anodized colors include clear or natural, black, red, blue, green, yellow, bronze, gold, gray, charcoal, copper, and brass. Clear anodizing maintains the silver-gray appearance of the metal while providing improved corrosion resistance, while black anodizing creates a deep black finish, and colored dyes can be added to achieve a range of vibrant hues for decorative or branding purposes. Anodizing can also replicate the look of materials like bronze, gold, copper, and brass, expanding its design possibilities. The specific shade and vibrancy of these colors may vary based on factors like the anodizing process, alloy type, and surface preparation.

While aluminum is generally regarded as safe for most individuals and usually doesn’t trigger skin reactions, some people may exhibit skin sensitivity or allergies to the metal, resulting in mild responses. The anodizing process effectively seals the aluminum surface, mitigating the risk of reactions from direct contact with the metal. Anodizing is considered a food safe surface coating and can be found on pots, pans, and cooking utensils. For individuals who have experienced skin reactions to aluminum or are concerned about potential long-term exposure issues, opting for anodized tuning forks provides a suitable solution, as the anodization provided a barrier to the aluminum.

Typically, tuning forks are manufactured with the tines slightly longer than required to achieve the desired vibration frequency. During the tuning process, the tines are carefully shortened to attain the precise frequency and accuracy needed. After achieving the desired frequency, the tuning fork can undergo the anodizing process for added protection and aesthetics. However, it’s important to note that anodizing can introduce very slight frequency alterations due to unpredictable variables in the anodizing process. Therefore, if a tuning fork has been anodized, it should be re-tuned afterward to ensure its vibrational frequency remains accurately calibrated.

After anodizing, it is crucial to tune the tuning fork to maintain accuracy. In cases where the tuning process has been completed, the tine ends will appear the natural silver color of the aluminum, as depicted here. If the tine ends match the fork’s color, it signifies that tuning was not conducted post-anodization, raising concerns about the fork’s accuracy.

This additional tuning process is typically required only on standard forks and usually not necessary on weighted forks unless it is significantly out of tune. Weighted forks can be tuned simply by making very small adjustments to the positions of the weights.

The drawback of tuning anodized forks is the removal of the anodized coating on the end of the tines. This not only detracts from the visual appearance but also results in sharp edges which require an additional process of de-burring to make it safe for handling. This additional de-burring can then influence the tuning.

To resolve these issues, Sacred Innovations has invented a tuning process we call “Hole Tuning”.

See the linked article to learn more about this process.

Sacred Innovations, your premier destination for precision instruments designed for sound therapy.

Copyright sacredinnovations.ca © All rights reserved