Hole Tuning is a specialized method used to fine-tune unweighted tuning forks with high precision.

Traditionally, tuning involves shortening the tines—usually through disc or belt sanding—to raise the fork’s frequency by removing small amounts of material from the tips. While effective, this method can be less precise and may introduce slight inconsistencies in tine length or surface finish.

Hole tuning offers an alternative approach. Instead of removing material from the ends, small holes are strategically drilled or deepened in specific areas of the tines. This subtly alters the mass distribution and vibrational characteristics without changing the overall tine length. The result is a more controlled and repeatable tuning process, with improved consistency across batches and no impact on the fork’s structural integrity.

Most tuning fork makers utilize a process of disc or belt sanding to remove small amount of aluminum from the ends of the tines.

This process does present some issues:

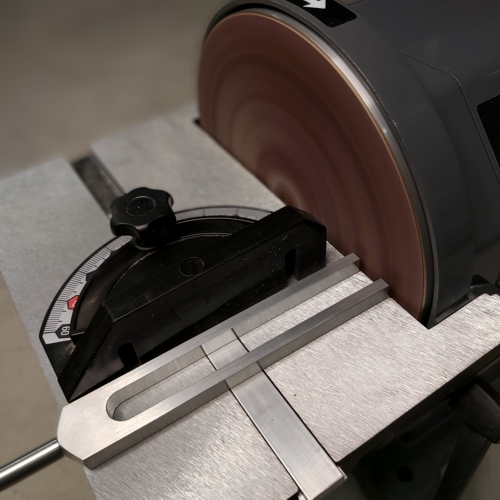

Hole Tuning is performed using specialized machinery designed and built by Sacred Innovations.

This custom-built equipment uses a precision carbide cutting tool to drill micro-holes into the ends of each tine. By selectively removing small amounts of aluminum, the mass is reduced in controlled increments, allowing for extremely accurate adjustment of the tuning fork’s fundamental frequency. This tuning process also ensures that both tines are tuned identically thus creating clear harmonic tones.

The system features an integrated depth gauge that measures the cutting depth with a precision of 1/1000 of an inch (0.001″). This ensures exact material removal and eliminates the risk of “over-tuning” by taking off too much aluminum.

Unlike traditional grinding methods, which can generate significant heat and require cooling cycles, the hole tuning process uses cutting lubricants to minimize heat buildup. As a result, the process is more efficient—requiring no repeated cooling or drying cycles—while maintaining the structural integrity of the fork.

Sacred Innovations, your premier destination for precision instruments designed for sound therapy.

Copyright sacredinnovations.ca © All rights reserved